Table of Contents

- DirectLink Introduction

- DirectLink Main Features

- How To Setup TR4 System

- About This Manual

- Troubleshooting

- TRo2/o2 Sensors/Rivnut Installation

- O2 Sensor Installation Kit Lite

- ECU Tuning Compatibility

- All TechnoResearch Cables

- Tuning Victory® Motorcycle

- Licensing

- 1 Setup and Installation

- 1.1 Where To Get The Software

- 1.2 Install Direct Link Flash Tuner

- 1.3 Run Direct Link Flash Tuner

- 1.4 Connect USB Cable

- 1.5 Power Up The Direct Link Flash Tuner

- 1.6 Power Up To Automatically Install Drivers

- 1.7 Update The Software

- 1.8 Confirm Com Port For Communication

- 1.9 Troubleshooting Com Port Issues

- 2. Toolbar Menu and Icon Descriptions

- 3. Direct Link – Key Features

- 4. Direct Link – Important Tables

- 5. Program the Calibration into the ECU

- 6. How to Save the Modified Calibration

- 7. How to Change Units and Colors

- 8. Monitor Real-Time Data

(Gauges/Meter Display) - 9. Monitor Real-Time Data

(Strip Chart/Meter Display) - 10. Auto-Mapping

- 11. Common Issues and

Possible Solutions - Glossary

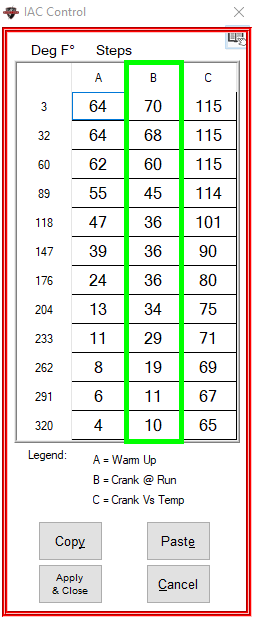

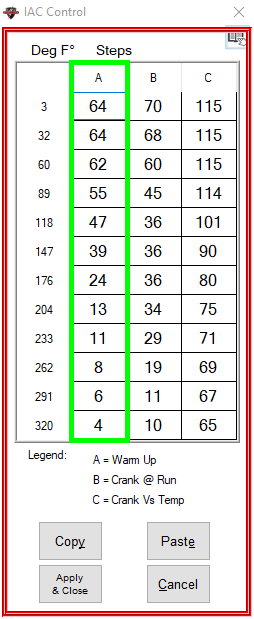

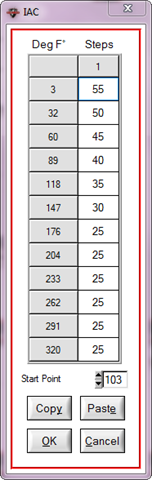

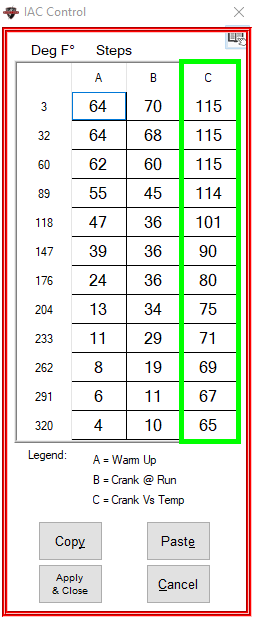

4.6 IAC Table

The IAC Table adjusts the Idle Air Control Step position of the motorcycle at 0%.

Increasing a value on this table will increase the engine airflow.

Decreasing a value on this table will decrease the engine airflow.

The table is in Steps vs Temperature. This table may need to be adjusted while tuning to make sure bike is idling up on startup, and when at operating temperature, the idle is stable. Check live data and verify that the actual stepper counts are not lower than the programmed stepper counts. The actual Steps should be the same or slightly lower than the programmed values. Double click on a STEPS cell and use the up and down arrow to adjust.

Newer model mappings will have 3 columns.

These three columns will control the duration and magnitude of the Idle Air cycle.(This is the Starting Point value on the single column IAC tables)

Example of usage: If a bike starts at 2200 RPM at ~ 150 degrees, but you would like it to start at 1600. Lower the value in Column C. It is a good rule of thumb to look at your desired RPM change and lower the IAC it by a similar ratio. (ie (1600RPM/2200RPM) * IAC current = IAC new.)

TIP: If, after lowering the Starting IAC values 25% or more, you see no change in the starting RPM, look for sources of uncontrolled air getting to the engine. Uncontrolled air = uncontrolled RPM.